Because of poor tube manufacturing or poor tube processing, 572B tubes have an abnormally high tendency to arc. This normally is not a problem to external equipment unless you have a radio that is abnormally sensitive to ESD (electrostatic discharge). Read the hint on soldering. I recommend the following steps to reduce voltages that appear on the INPUT port during tube faults:

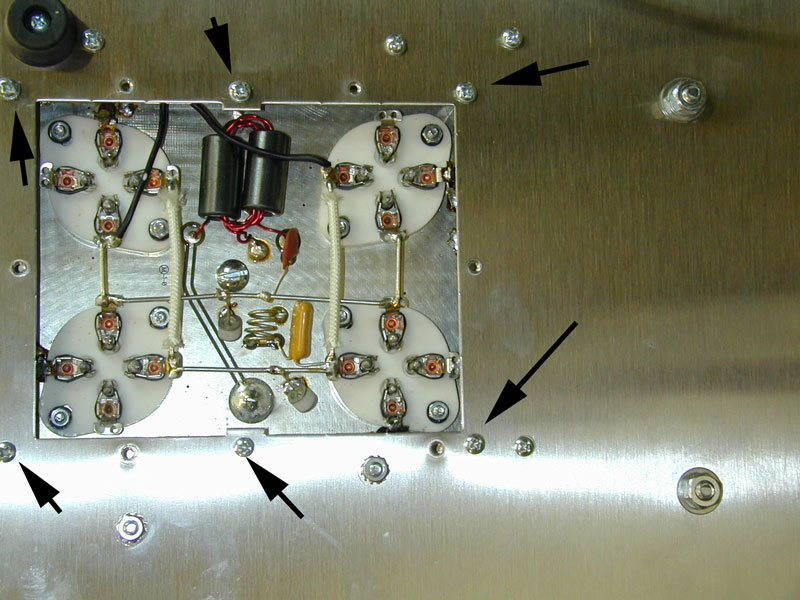

1.) Remove the cover, tubes, and turn the amplifier upside down.

2.) Remove the six screws that hold the service plate under the tubes, and remove that plate.

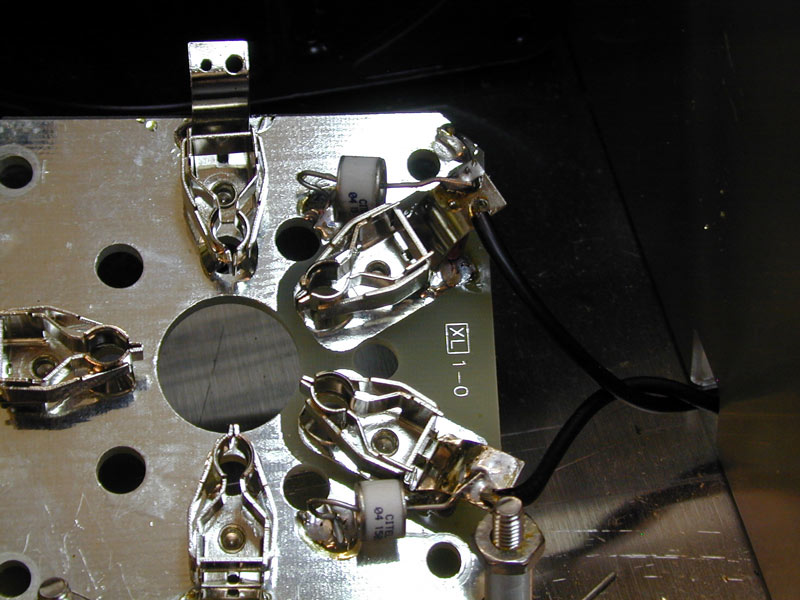

3.) Remove the six screws that hold the tube "chassis plate" to the cabinet bottom. This will allow some careful movement of the chassis so the small black grid resistors and orange or red .01 uF bypass capacitors can be removed.

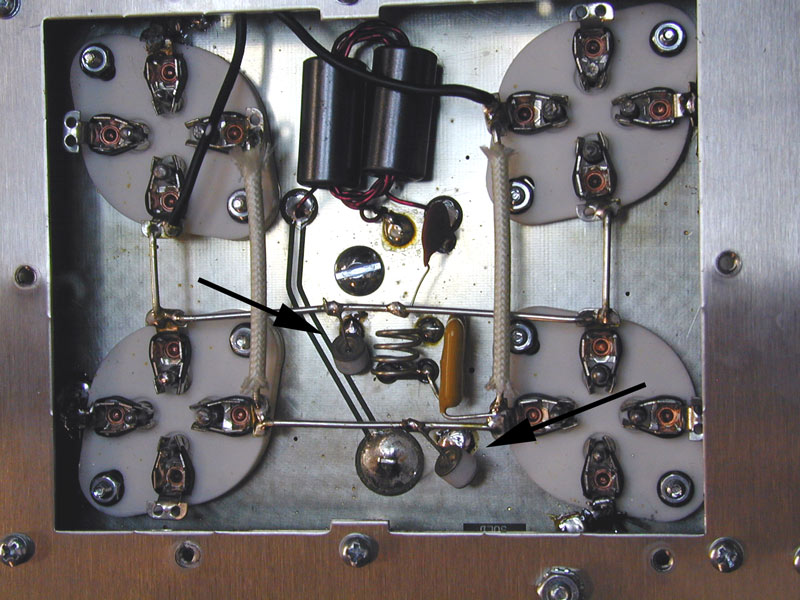

4.) Remove the 51 ohm resistors and .01uF capacitors at each grid pin, and directly ground the grids with the shortest possible connection. Use small braiding like the shield stripped from RG58 cable.

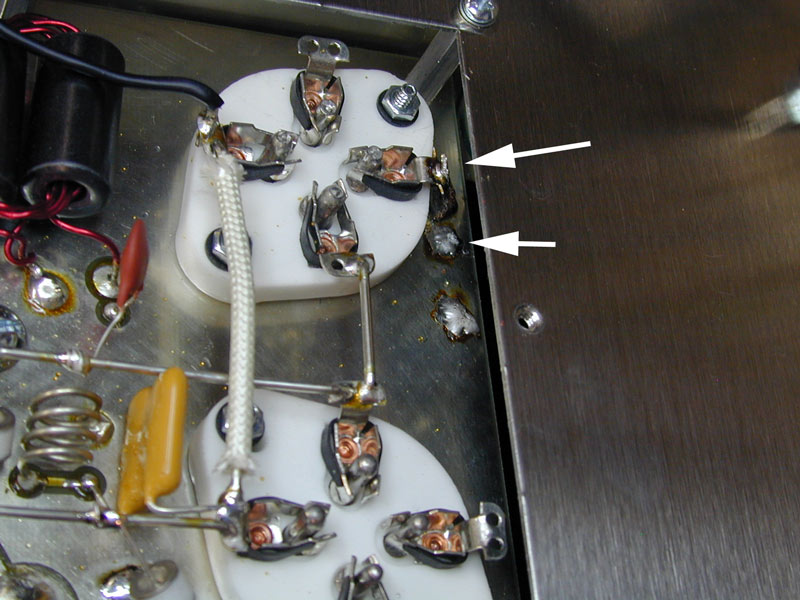

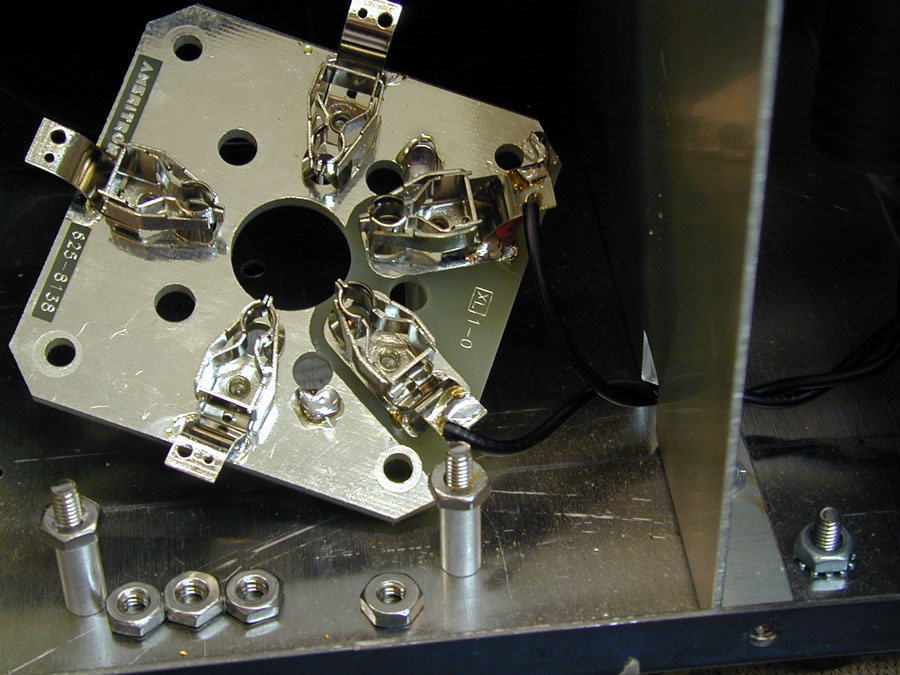

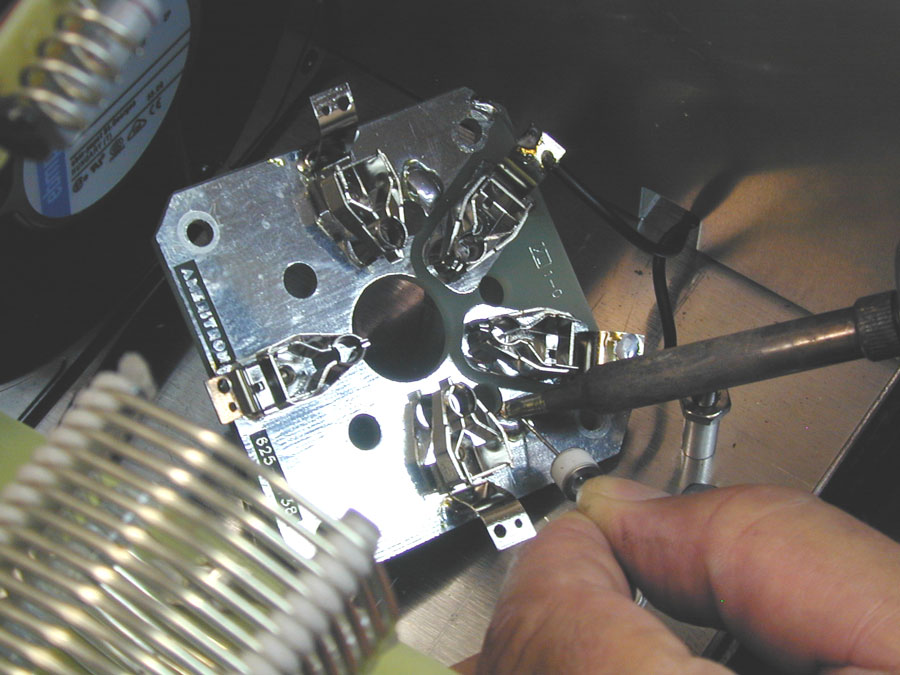

5.) Install two 150-volt to 170-volt gas voltage protectors.

Hint on soldering parts or connections to "no hole" PC boards and socket pins:

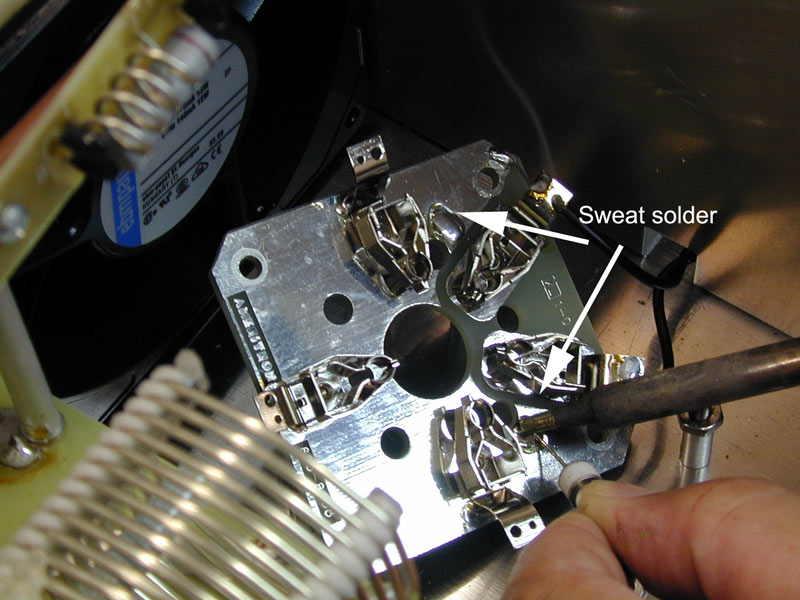

This is an AL80B socket, but the same principle applies.

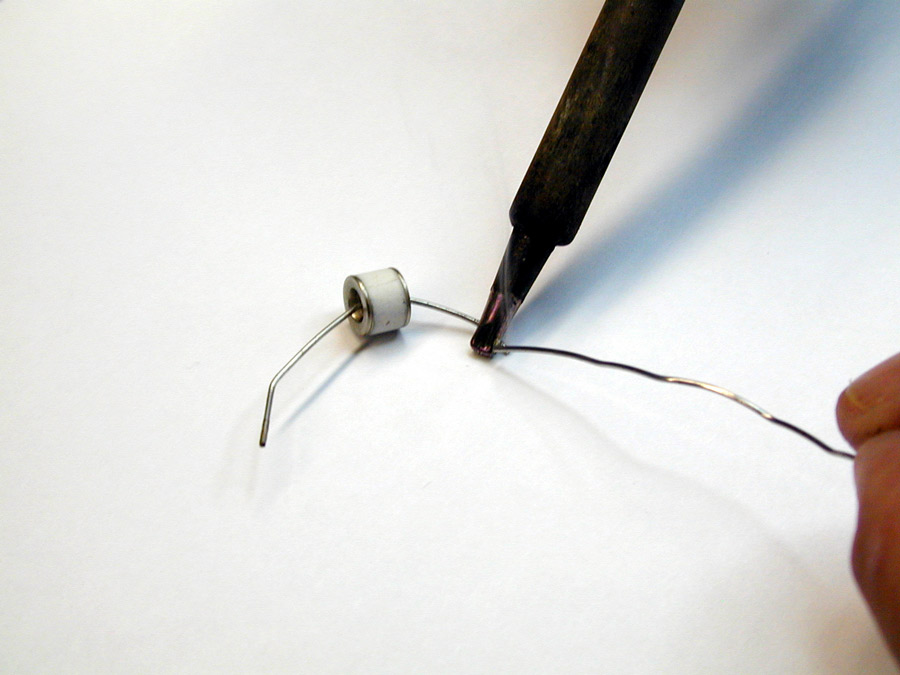

1.) Pre-tin component lead with a generous amount of fresh solder

2.) The component should have a slight excess of clean fresh solder on the point where you want to solder.

3.) You also want to pre-tin the area of the board you want to solder to, or the socket tab, with a slightly excessive amount of fresh solder.

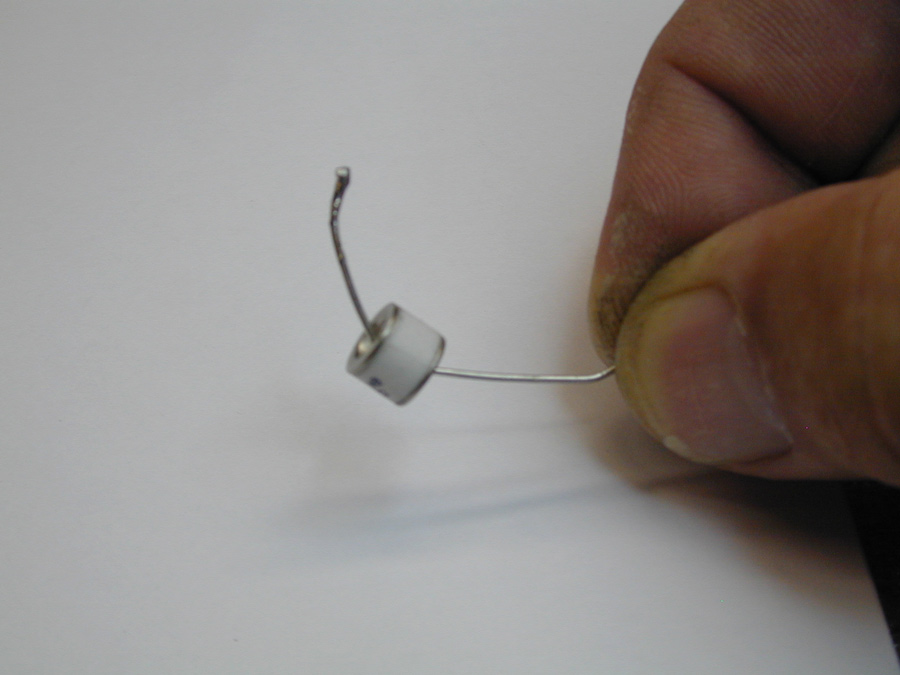

4.) Notice the slight excess of solder near the holes where the part will attach. The component is sweat soldered in place as shown. Just hold steady in place and heat until solder fully reflows

5.) This is a sweat-soldered AL80B protection system. The connections are tested by pulling. Even if the leads are pulled very hard, they will not detach.